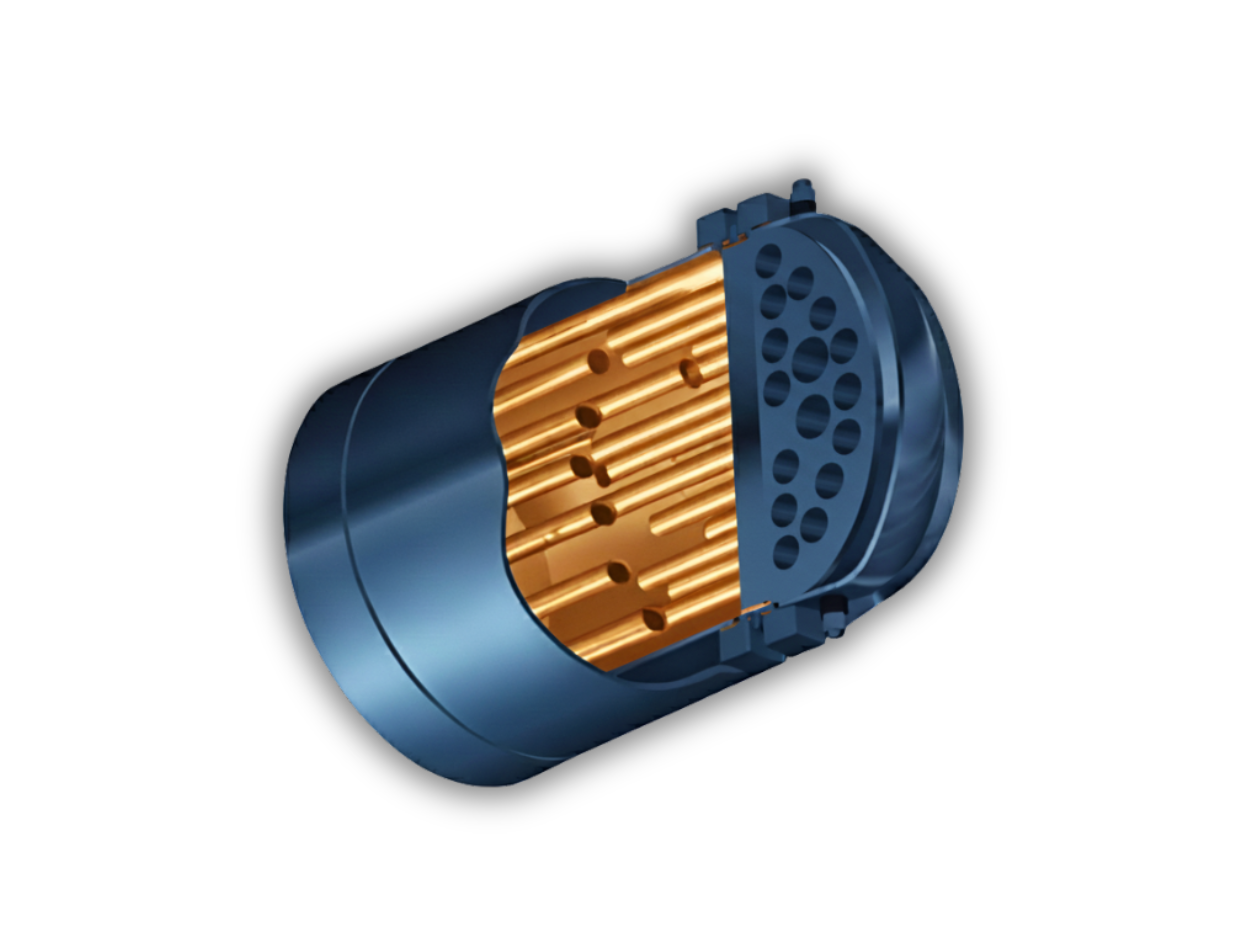

Tube Sheets

Excellence Through Consistency in High-Demand Environments

In the world of critical process engineering, the performance, safety, and longevity of heat exchangers and pressure vessels rely on high-quality tube sheets. At Shockwave Metalworking Technologies, we manufacture premium cladded tube sheets built for the most rigorous operational environments. Our solutions provide exceptional corrosion resistance, superior dimensional stability, and long-term performance, ensuring operational efficiency even under extreme conditions.

Minimizing operational downtime is critical. That’s why our cladded tube sheets are suitable for emergency replacements and fast maintenance cycles. With industry-leading turnaround times and verifiable quality, Shockwave delivers reliable solutions that reduce interruptions and maximize asset availability.

Shockwave Technology: The Foundation of Superior Tube Sheets

The unmatched integrity and quality of our cladded tube sheets are built from our proprietary Vacuum Explosion Cladding technology. This innovative vacuum-based process is the key to creating a 100% homogeneous bond between the base material and the selected clad material, an essential requirement for preventing material failure in aggressive media. The result is a zero leakage bond that offers a structural reliability far beyond what is possible with traditional methods.

To further ensure the absolute best performance, we apply advanced vacuum cladding techniques during production and machining. This significantly reduces residual stress within the tube sheet material. This meticulous process allows us to achieve and maintain exceptional flatness up to 1 mm/m across all dimensions.

Our technology is highly versatile, supporting an extensive range of material combinations and leveraging high-performance stainless steels, duplex grades, nickel alloys, and titanium. Shockwave can provide fully customized, engineered solutions perfectly tailored to your specific process requirements.

Applications Across High-Demand Industries

Due to their exceptional material integrity and resistance to extreme operating conditions, Shockwave claddedtubesheets are the preferred choice for critical equipment in some of the world’s most demanding industries. Our products ensure reliable, leak-free operation where component failure is simply not an option.

We serve clients across key sectors, including:

- Oil & Gas and Petrochemical: Used in reactors, fractionation columns, and complex heat exchangers exposed to highly corrosive process media.

- Chemical Processing: Essential for processes involving aggressive acids, high pressures, and high-temperature environments.

- Power Generation: Utilized in feedwater heaters and condensers, where both erosion and corrosion resistance are vital.

- Fertilizers and Mining: Providing long-term stability against chemical attack and abrasive materials.

Technical Data & Customization

Shockwave Metalworking Technologies is equipped to handle projects of significant scale and technical complexity, offering one of the most extensive ranges of cladded tube sheets available in the industry.

We take pride in our ability to offer custom cladding combinations and bespoke solutions to meet your precise operational requirements, including a wide variety of diameters, thicknesses, and material combinations.

For a complete list of standard sizes, detailed material specifications, and full technical data, please download our official Tube sheets Brochure.

Key Performance Feautures of Tube Sheets

100% Homogeneous Bond: Ensures zero leakage and complete structural integrity between base and clad layers, essential for safety and longevity

Outstanding Corrosion Resistance: Significantly extends the operational lifespan in harsh chemical, thermal, and high-pressure environments

High Dimensional Stability: Achieves precise flatness (up to 1 mm/m), ensuring a perfect seal and precise fit within the heat exchanger shell

Stress-Reduced Material: Our vacuum cladding process minimizes internal residual stress, dramatically enhancing overall reliability and mitigating the risk of premature failure

Efficiency and Sustainability Through Shockwave Technology

The high-integrity bonding process achieved through Shockwave Technology is inherently linked to both superiorefficiency and sustainability.

Enhanced Efficiency:

The guaranteed zero leakage, 100% homogeneous bond dramatically increases the lifespan of the tube sheet, minimizing the need for frequent replacements and reducing overall maintenance costs. Furthermore, the vacuum cladding process reduces residual stresses, ensuring the dimensional stability required for optimal heat transfer performance throughout the component’s operational life.

Sustainability Benefits:

Cladding is an inherently sustainable material solution. By using an economical, heavy-gauge base material and only applying a thin, high-performance layer of expensive, corrosion-resistant clad material where it is truly needed, we significantly reduce the consumption of high-cost, high-impact alloys. This targeted material usage, combined with the extreme durability of the bonding process, results in lower life-cycle costs and a reduced environmental footprint.

Download Data Sheet

If you’d like us to send you the technical data sheet for this product, please fill out this form and we’ll send it to you right away.