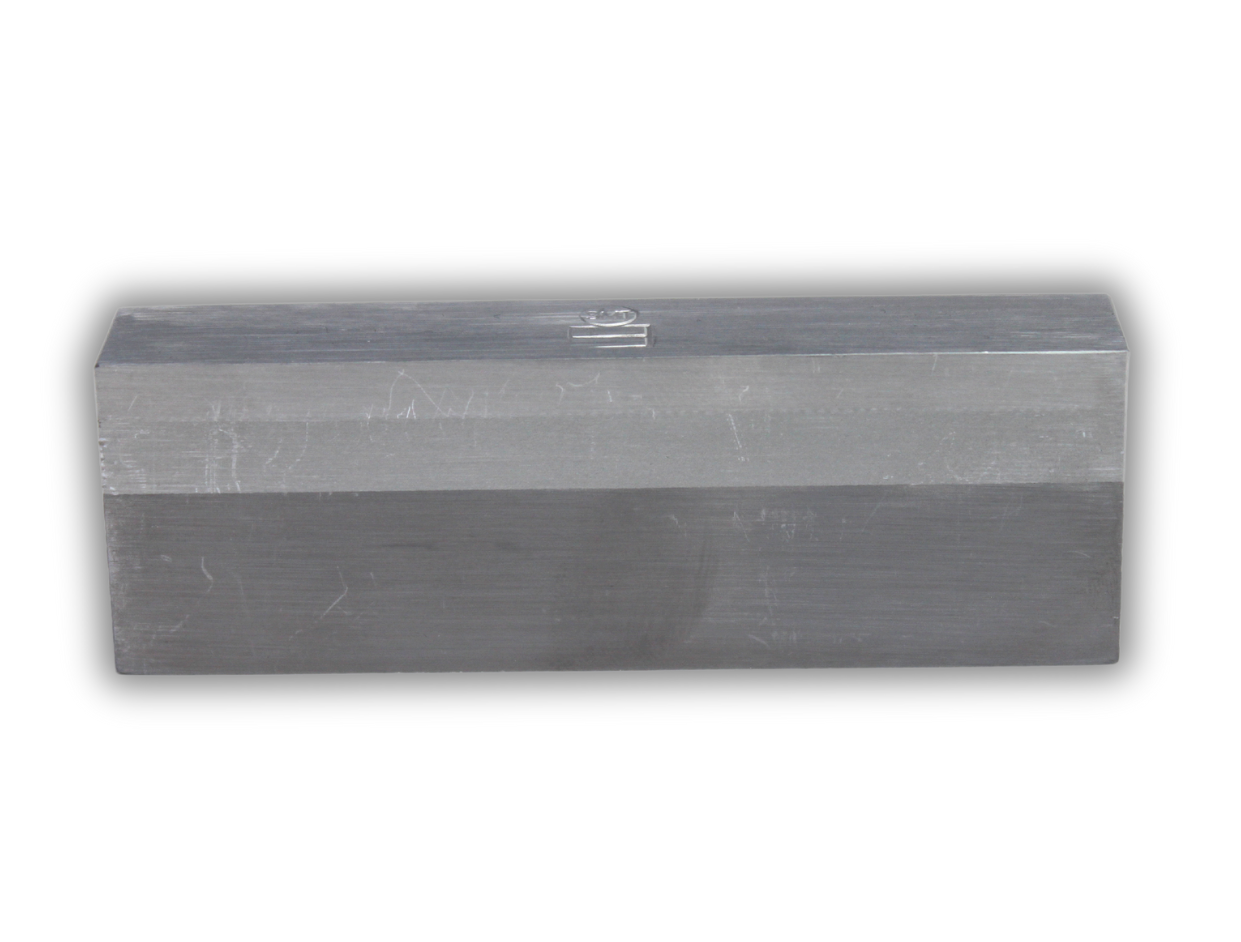

Triplate®

The Leading Trimetallic Transition Joint

What makes Triplate® unique?

Manufactured using advanced vacuum explosion welding, Triplate® creates a continuous metallurgical bond between aluminium and steel. Unlike direct welding or mechanical fastening, this solid-state process delivers a permanent, defect-free connection with superior protection against marine corrosion.

Applications in Shipbuilding and Offshore Construction

Triplate® transition joints are primarily used in:

- Shipbuilding: transition joints between steel hulls and aluminium superstructures, reducing weight without compromising safety.

- Offshore construction: connecting aluminium living modules to steel structures on platforms and support vessels.

Triplate® is trusted in naval ships, high-speed ferries, passenger vessels, and offshore projects operating in extreme environments.

Certified Quality & Proven Reliability

With an impeccable record—not a single joint failure since 2008—Triplate® meets the highest international standards, including MIL.J-24445A, and holds approvals from Lloyd’s Marine, DNV, and ABS. Each joint undergoes rigorous testing to ensure resistance to fatigue, galvanic corrosion, and mechanical stress. Triplate® is the only transition joint that guarantees a 100% dense interface, verified through dye-penetrant testing.

Advantages of Triplate®

Permanent, maintenance-free connection

Excellent mechanical strength and corrosion resistance

Certified solution for naval and offshore industries

Proven reliability in international projects

The Ultimate Solution in Naval Transition Joints

With Triplate®, Shockwave delivers a high-performance transition joint trusted by shipyards and engineering companies worldwide. For certified, dependable aluminium-to-steel bonding, Triplate® is the safe choice.

Download Data Sheet

Please complete the form below to receive the brochure via email within a few minutes.