Technology

Vacuum Explosion Cladding

At Shockwave Metalworking Technologies, we specialize in producing clad plates using advanced vacuum explosion welding. This state-of-the-art process enables the bonding of metals that cannot be joined by conventional welding methods, resulting in exceptionally strong, oxide-free connections with outstanding mechanical and chemical performance.

What is Vacuum Explosion Cladding?

Explosion cladding fuses two or more dissimilar metals through a high-velocity oblique impact generated by controlled explosives. Within a vacuum chamber, this process creates extreme pressures that form an atomic, solid-state bond—without melting or causing thermal distortion.

The outcome is bi-metallic and tri-metallic plates that preserve the unique properties of each metal while delivering superior strength, durability, and performance in the most demanding environments.

Clad Plate Manufacturing Process

Material Preparation & Inspection

Assembly

Explosive Placement

Vacuum Chamber

Controlled Detonation

Finishing

Quality Control

Packaging & Delivery

Advantages of the Vacuum Process

Shorter Lead Times

Superior Process Control

Higher Precision

Cost Efficiency

Unmatched Flexibility

Preserved Material Integrity

Exceptional Bond Strength

Perfect Finish

Main Applications of Clad Plates

Our vacuum explosion welded clad plates are relied upon in industries where resistance to corrosion, pressure, wear and temperature is essential:

Oil & Gas

Chemical & Petrochemical

Power Generation

Desalination Plants

Cryogenic industry

Steelmaking & Hydrometallurgy

Aluminum Foundries

Shipbuilding

And many more

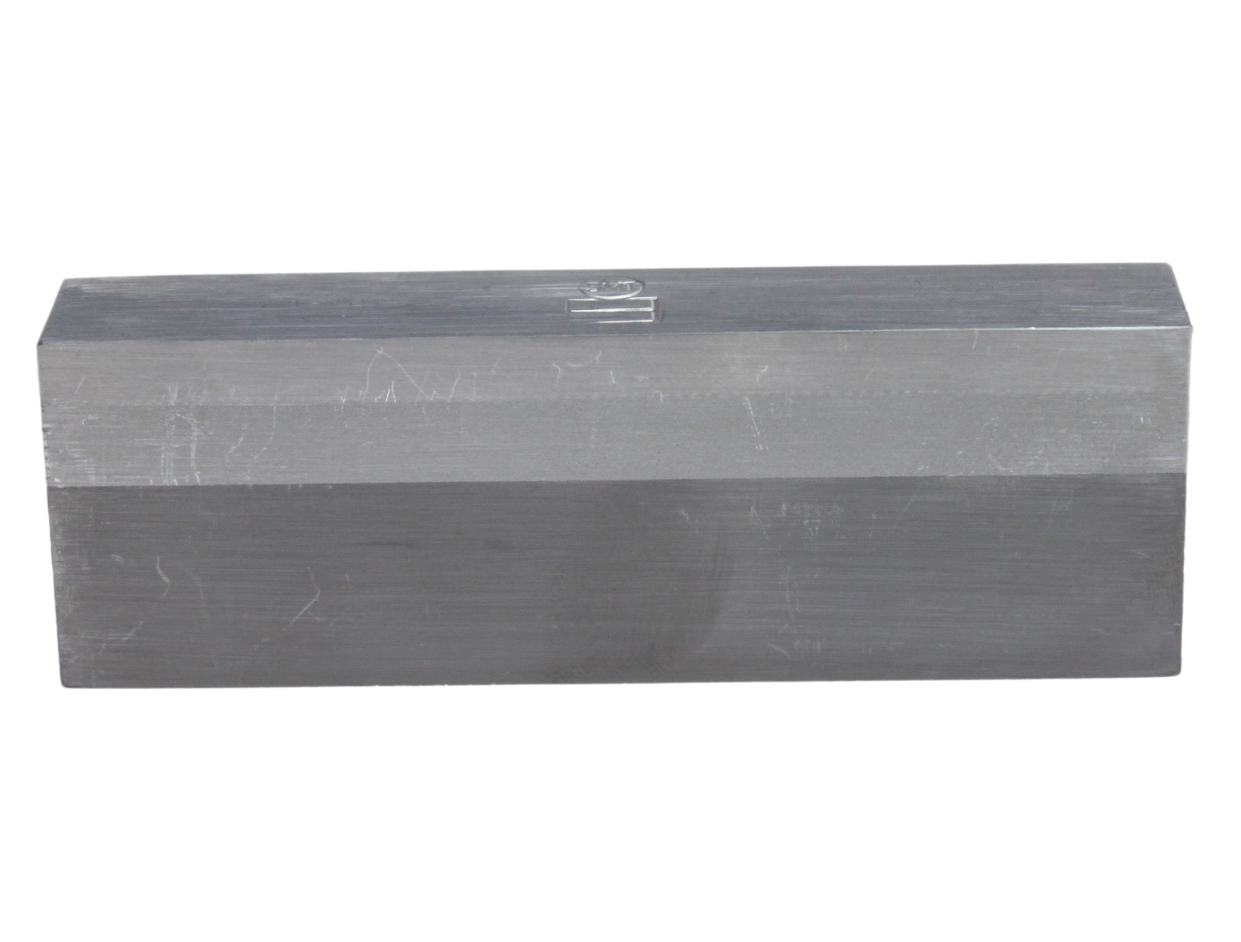

Vacuum Cladding

- 100% Dense

- 100% quarantee on Dye-Penetrant

- Optimized ductility, no cracks during bending

- Optimized fatigue strength

- No crevice or galvanic corrosion

- Asymmetric welding is acceptable

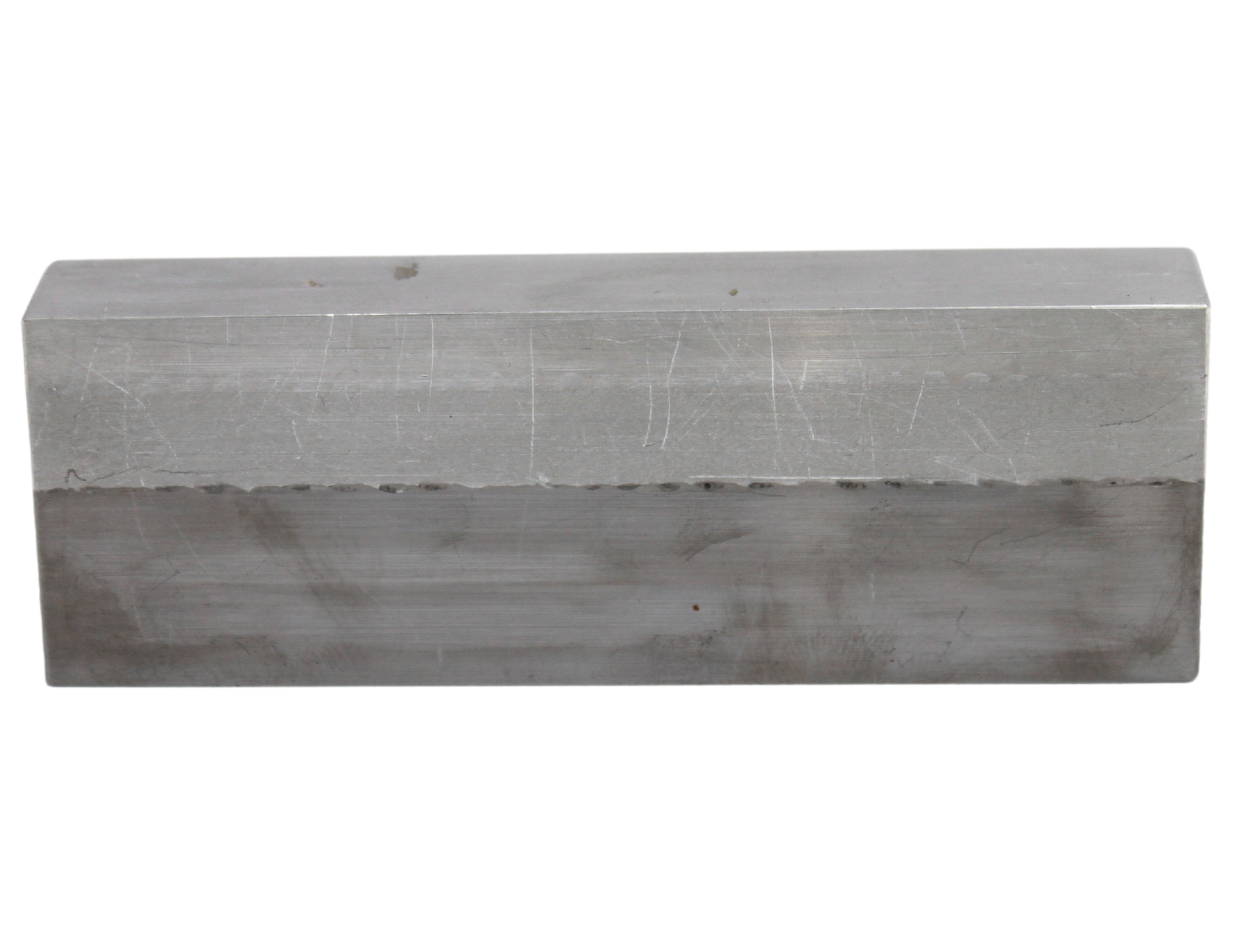

Open Air Cladding

- Intermetallics on the interface

- No Dye-Penetrant guarantee

- Cracks during bending

- Limited fatigue strength

- Oxides on the interface initiate corrosion

- Not acceptable due to more brittle interface