Clad Plates

Innovation and Performance for the Most Demanding Industries

With more than six decades of experience in joining dissimilar metals, Shockwave Metalworking Technologies has become a global leader in the production of high-quality clad plates. Our products combine strength, durability, and precision, meeting the needs of the most demanding industrial sectors.

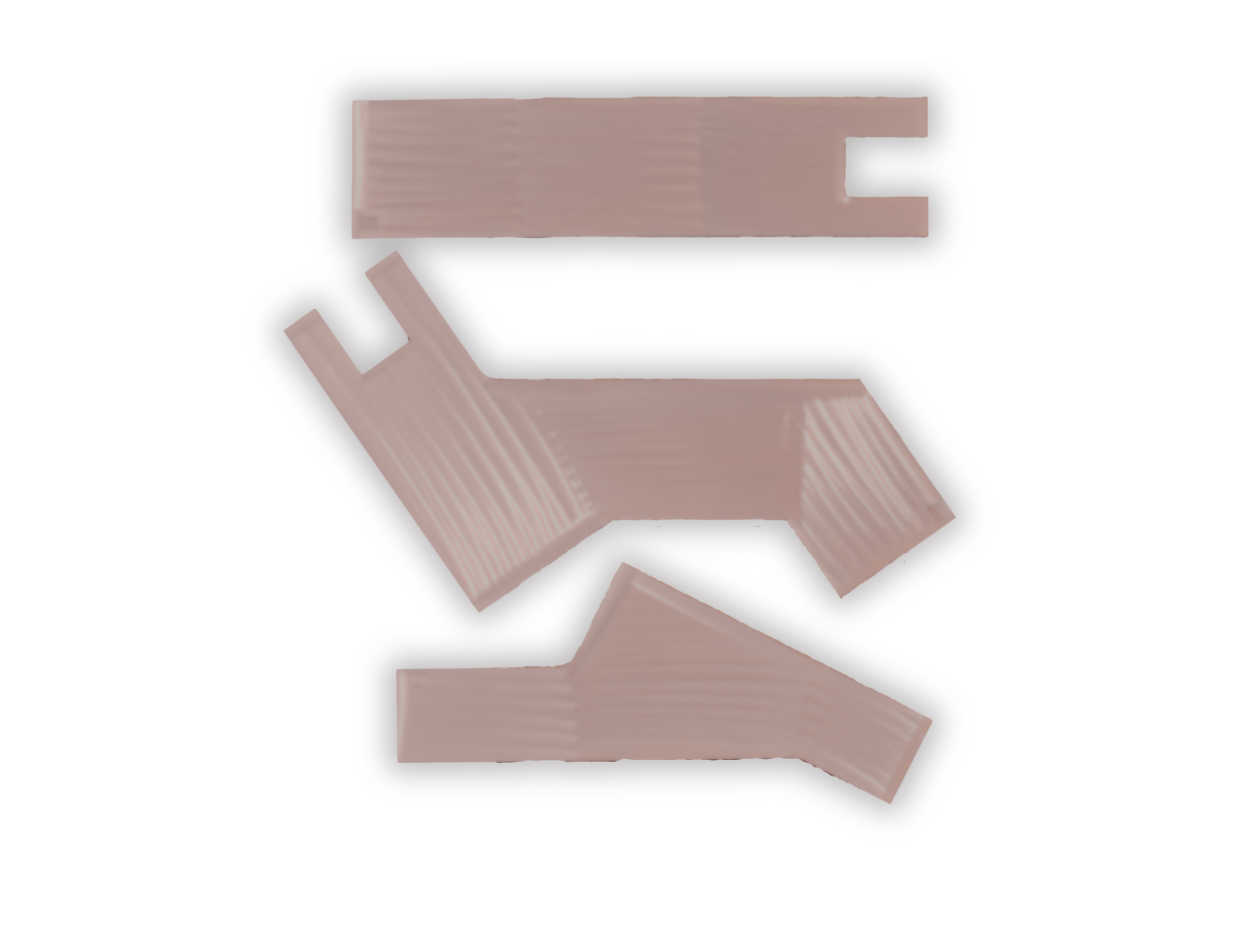

What Are Clad Plates?

Clad plates are composite materials formed by joining two or more different metals.

They combine the best properties of each metal, pairing the mechanical strength of the base metal with the resistance of the cladding layer.

The cladding provides protection against corrosion, wear, and high temperatures. This technology enables the production of lighter, more efficient, and longer-lasting components.

It performs reliably even in harsh environments exposed to extreme heat or aggressive chemicals.

Shockwave Technology: Vacuum Explosive Welding

At Shockwave Metalworking Technologies, we use an exclusive vacuum explosive welding process — an advanced technique that ensures a perfect metallurgical bond between dissimilar metals without altering their original properties.

This method uses the controlled energy of an explosion to fuse metal layers instantly and uniformly, creating an exceptionally strong bond. Unlike traditional thermal methods, explosive welding does not require significant heat input, which minimizes deformation, internal stress, and bonding defects.

Our process is carried out under vacuum conditions, which reduces environmental impact and enhances product quality. Thanks to this technology, we achieve a reduction of more than 40,000 tons of CO₂ emissions per year, reinforcing our commitment to sustainability and responsible innovation.

Capabilities, Dimensions, and Materials

Our industrial clad plates are manufactured to the highest standards of quality and precision. We offer a wide range of dimensions, thicknesses, and material combinations tailored to each specific application.

Shockwave works with an extensive selection of base and cladding metals, including stainless steels, duplex steels, titanium, tantalum, nickel and nickel alloys, aluminium, copper, and various steel alloys — ensuring optimal performance in terms of corrosion resistance, conductivity, and structural integrity.

For detailed information about our manufacturing capabilities, sizes, and available metal combinations, we invite you to download our technical brochure here.

Industrial Applications

Shockwave clad plates are used in a wide range of industries where reliability and strength are essential:

- Oil & Gas (onshore and offshore)

- Power generation (hydroelectric and thermal)

- Chemical and petrochemical industries

- Shipbuilding and offshore platforms

- Aluminium foundries and steel mills

- HVAC and industrial cooling systems

- Pharmaceutical industry

- Desalination plants

- Renewable energy

Thanks to their performance and versatility, our clad plates offer extended service life, reduced maintenance costs, and improved operational efficiency in the most demanding environments.

Commitment to Quality and Sustainability

At Shockwave Metalworking Technologies, innovation is at the core of everything we do. Each clad plate is the result of rigorous quality control, advanced engineering, and deep metallurgical expertise.

We combine state-of-the-art technology, high-performance materials, and responsible processes to deliver products that exceed the expectations of the global industrial market.

Download Data Sheet

If you’d like us to send you the technical data sheet for this product, please fill out this form and we’ll send it to you right away.