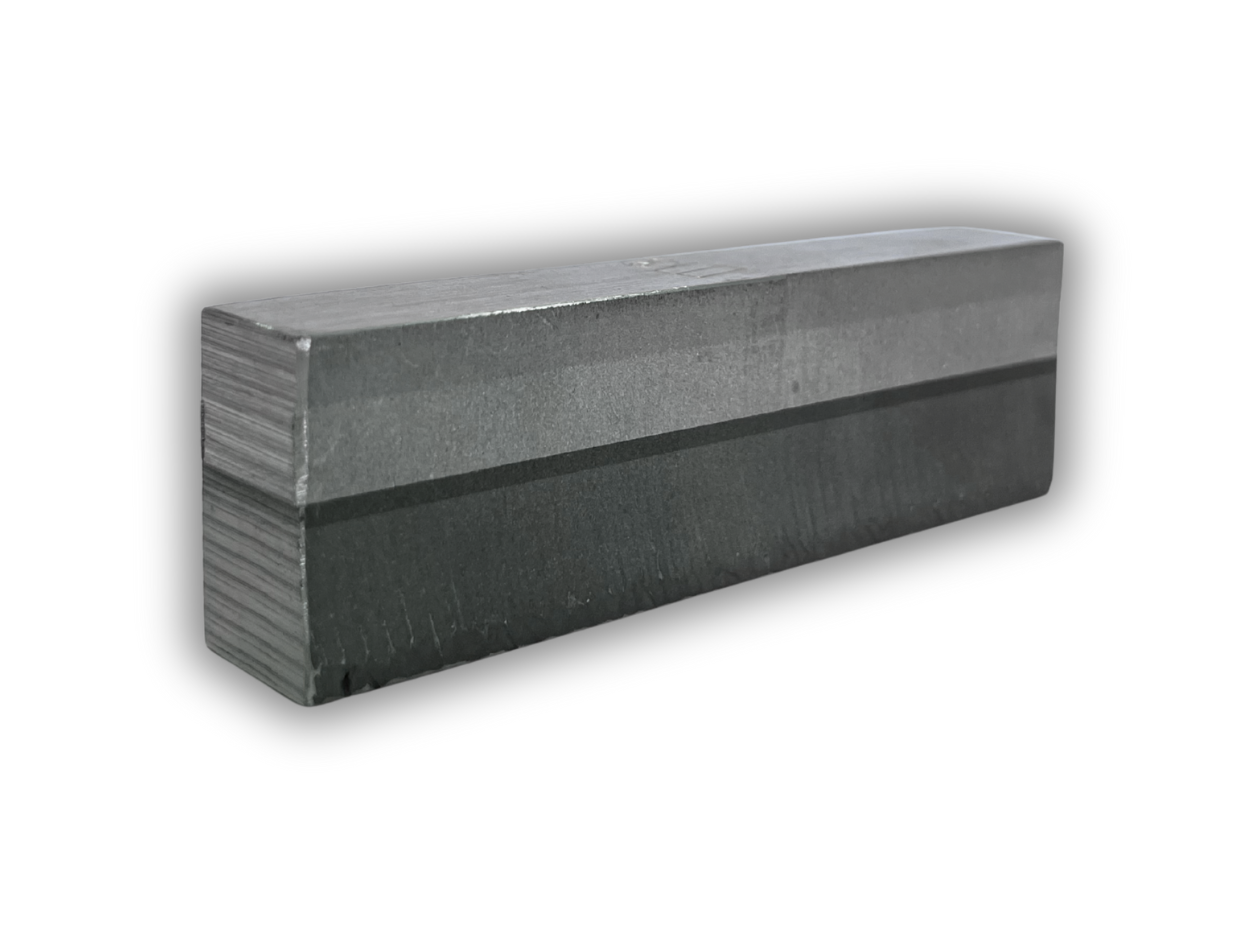

Inox Triplate®

High-Performance Transition Joint

Certified Quality and Mechanical Reliability

The vacuum explosion welding process represents a major improvement over open-air cladding method. It requires significantly less explosive material and reduces emissions by up to 250 tons of CO₂ per year. As a closed system, it also filters process gases before release, making Inox Triplate® not only a high-performance solution but also the most sustainable choice for modern engineering projects.

Critical Applications of Transition Joints

Triplate® transition joints are primarily used in:

- Shipbuilding: transition joints between steel hulls and aluminium superstructures, reducing weight without compromising safety.

- Offshore construction: connecting aluminium living modules to steel structures on platforms and support vessels.

Triplate® is trusted in naval ships, high-speed ferries, passenger vessels, and offshore projects operating in extreme environments.

Certified Quality & Proven Reliability

Inox Triplate® is the ideal choice for projects requiring stainless steel structural transition joints between carbon steel and stainless steel. Its proven design ensures mechanical strength, durability, and stability in naval, offshore, and heavy transportation applications. It simplifies integration into complex structures, reduces fabrication risks, and guarantees reliable long-term performance. Inox Triplate® delivers efficiency, safety, and confidence in every metal transition.

Advantages of Inox Triplate®

Permanent, maintenance-free connection

Excellent mechanical strength and corrosion resistance

Proven reliability in international projects

Certified solution for naval and offshore industries

Download Data Sheet

If you’d like us to send you the technical data sheet for this product, please fill out this form and we’ll send it to you right away.