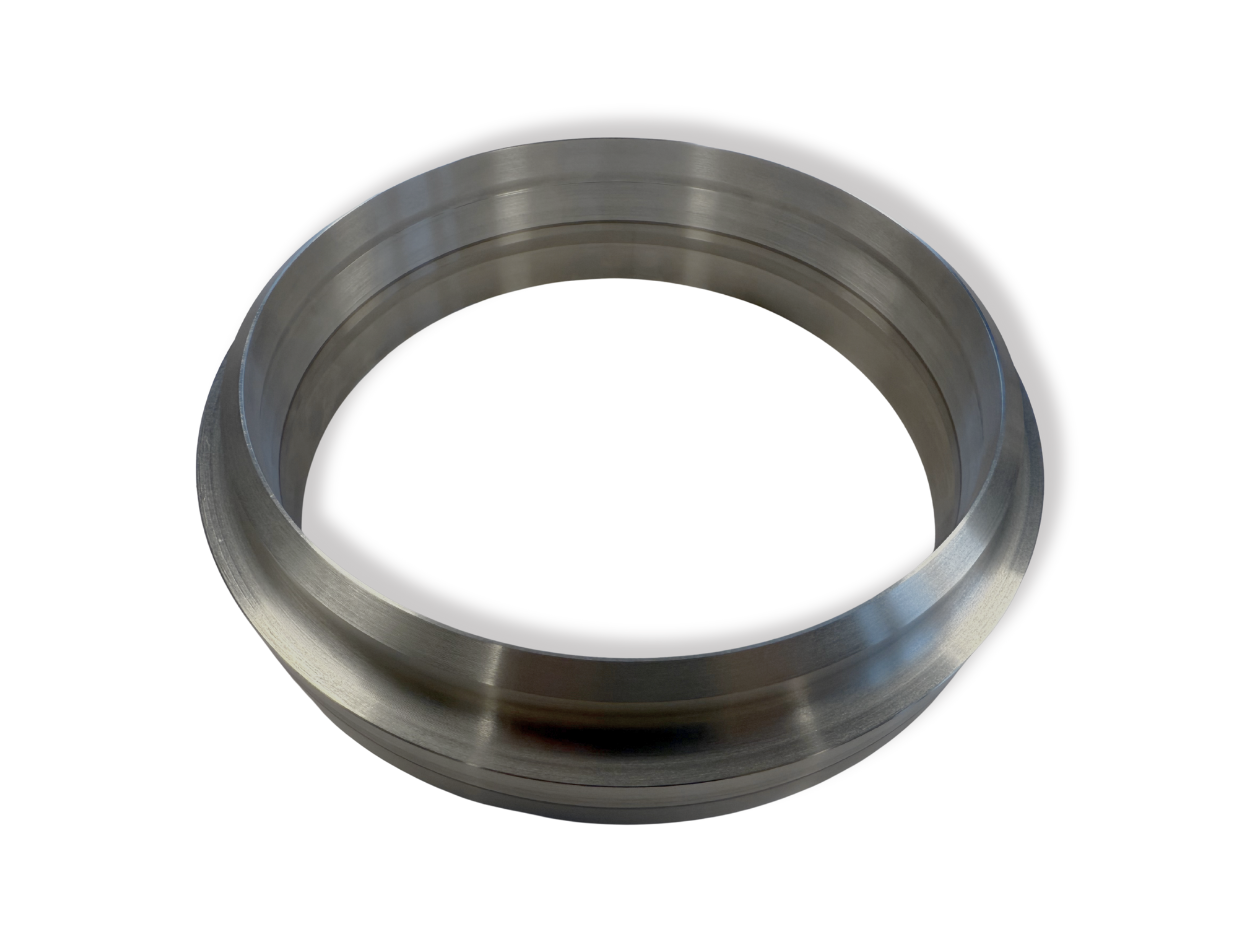

CryoClad®

The Cryogenic Transition Joint that Connects the impossible

In applications where reliability and structural integrity are critical, such as liquid hydrogen storage, LNG facilities, aerospace propulsion, or ultra-high vacuum systems, only one technology ensures a perfect connection: CryoClad®, the cryogenic transition joint developed by Shockwave Metalworking Technologies.

CryoClad® is a multilayer cryogenic plate designed to join dissimilar metals with a 100% dense, oxide-free, and defect-free interface, even under extreme cryogenic temperatures, high pressure, and vacuum.

Thanks to Shockwave’s exclusive vacuum explosive bonding technology, CryoClad® delivers unmatched metallurgical integrity, reliable performance, and long-lasting durability.

Guaranteed Quality for Cryogenic Transition Joints

Every CryoClad® cryogenic transition joint undergoes rigorous non-destructive testing (NDT) to ensure complete reliability before delivery.

Quality and testing procedures include:

- Liquid penetrant inspection to verify there are no microcracks or surface imperfections in the bonded interface.

- Helium leak testing with sensitivity up to 10⁻¹⁰ mbar·l/s, ensuring a fully hermetic seal.

These tests confirm a defect-free, oxide-free joint, with maximum metallurgical integrity and extended service life under the most demanding conditions, making CryoClad® one of the most reliable cryogenic transition joints available on the market.

Patented Vacuum Explosive Bonding Technology for Cryogenic Joints

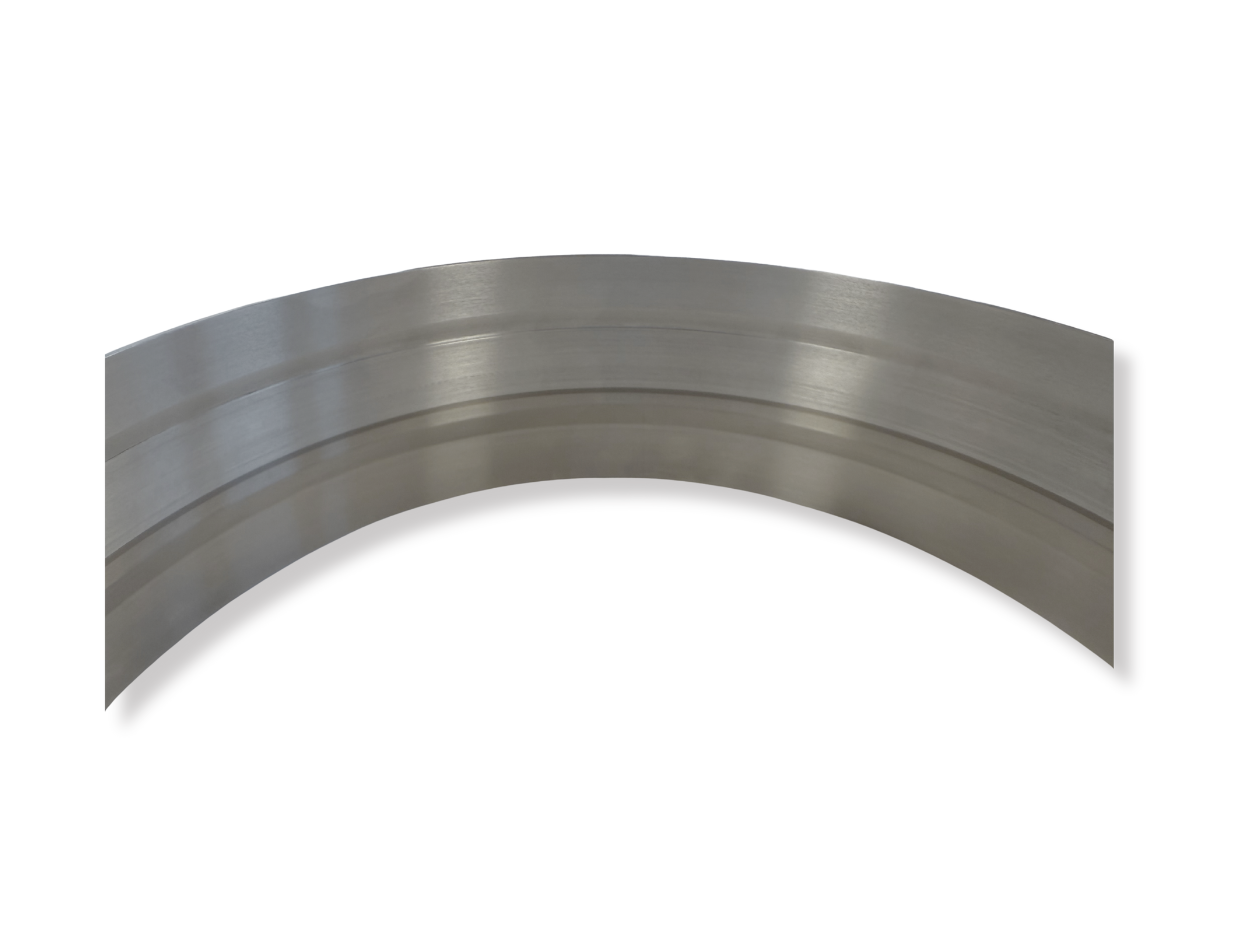

At the heart of CryoClad® lies Shockwave’s patented vacuum explosive bonding process.

Unlike conventional methods, this technology enables fabrication in a fully vacuum environment, preventing oxide formation and ensuring a pure, continuous metallurgical interface.

Thanks to this process, CryoClad® cryogenic joints achieve:

- Perfect bonding across the entire plate, free of discontinuities.

- Pressure resistance exceeding 360 bar.

- Batch-to-batch repeatability and consistency performance.

This precision makes CryoClad® the ideal solution for applications such as hydrogen storage tanks, LNG infrastructure, and aerospace propulsion systems.

Materials and Configurations

CryoClad® is available in various material combinations and multilayer configurations, tailored to each project’s specific requirements. It enables efficient joining of stainless steel, titanium, aluminium, and special alloys, ensuring a stable and reliable cryogenic transition between metals with different thermal and mechanical properties.

CryoClad® is available in a range of thicknesses and sizes, adaptable to the dimensions and pressure requirements of each installation, while maintaining consistent quality and performance in every cryogenic transition joint.

To explore all available configurations and detailed technical specifications, download our brochure here

Efficiency and Sustainability of Cryoclad

Shockwave’s vacuum explosive bonding process uses only a fraction of the explosives required by traditional methods and filters explosion gases before release, minimizing environmental impact.

Thanks to this innovation, CryoClad® prevents over 250 tons of CO₂ emissions per year, making it a cleaner, safer, and more responsible choice for high-performance industries.

Main Applications

CryoClad® cryogenic transition joints are used in industries where reliability is essential:

- Cryogenic hydrogen and LNG storage tanks

- Aerospace and propulsion components

- Vacuum systems, cryostats, and heat exchangers

- High-pressure aluminium-stainless steel transitions

Advantages of Choosing Cryoclad®

Metallurgical bonding without bolts or thermal welding

Zero leaks, zero oxides, zero defects

Exceptional resistance to pressure and thermal fatigue

Sustainable manufacturing with full traceability

CryoClad® — Connecting the Impossible

A cryogenic transition joint offering total structural integrity, proven performance, and a genuine environmental commitment.

CryoClad® connects what nothing else can connect.

Download Data Sheet

If you’d like us to send you the technical data sheet for this product, please fill out this form and we’ll send it to you right away.